1. Connect

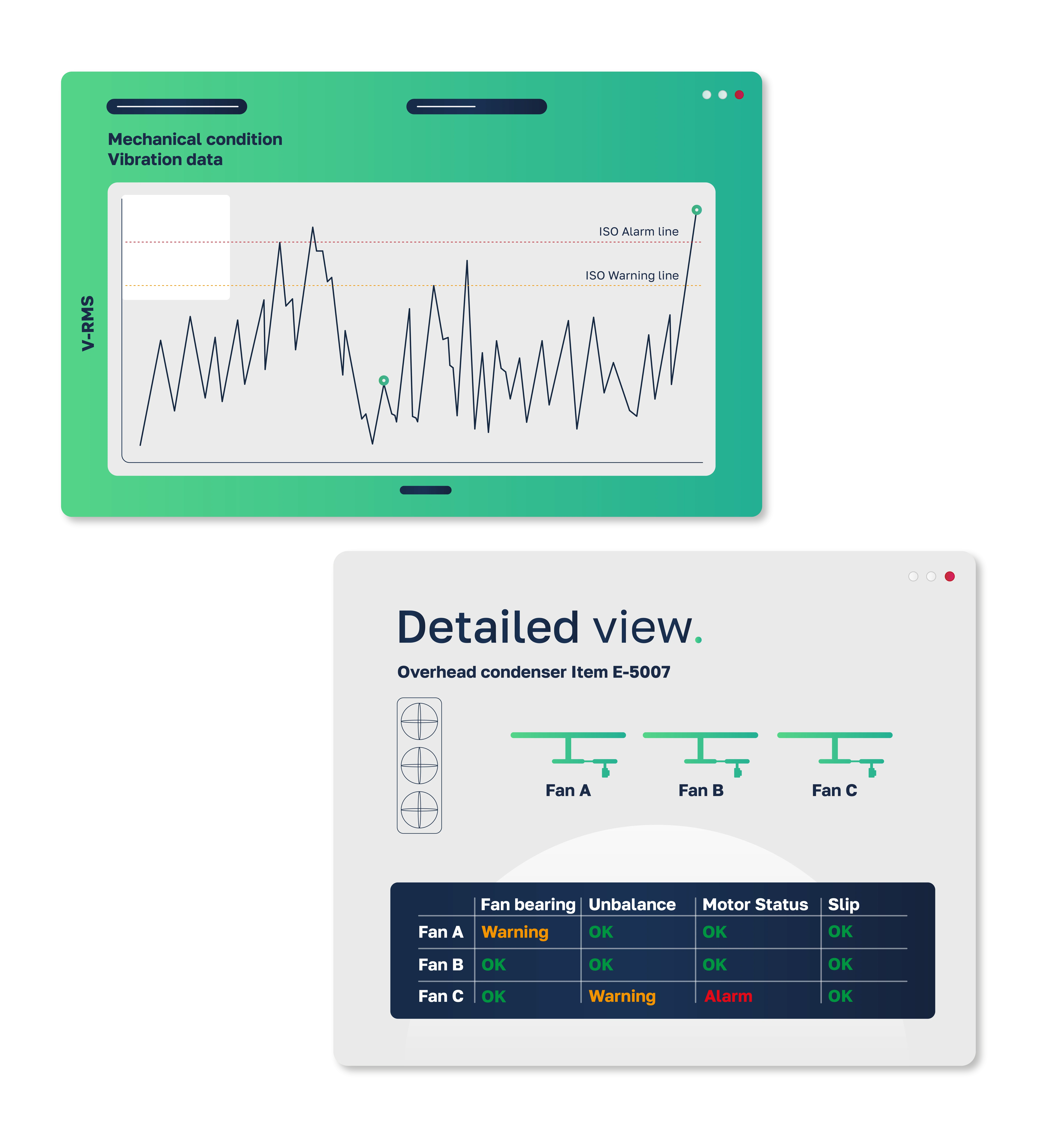

We connect your air-cooled cooling system to our digital environment, enabling continuous visibility of their operational status and performance.

Our platform connects to a wide range of data sources. Depending on your setup, we can run our algorithms from data exports, direct connections to DCS and other plant systems, or via a stand-alone IoT deployment. Every option follows rigorous cybersecurity and asset-safety standards.